The Transformation of the Province's Fishery through Innovation

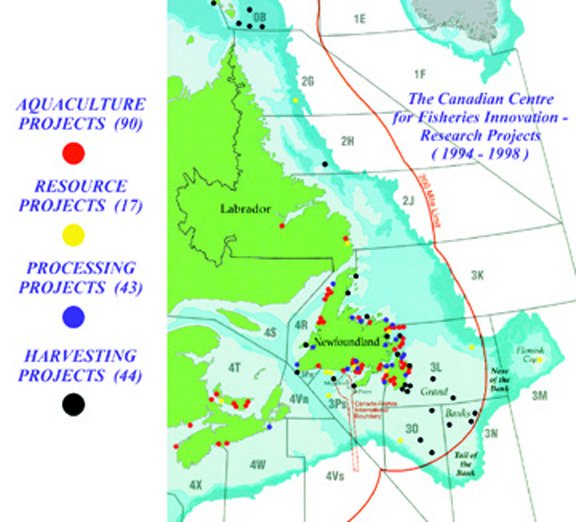

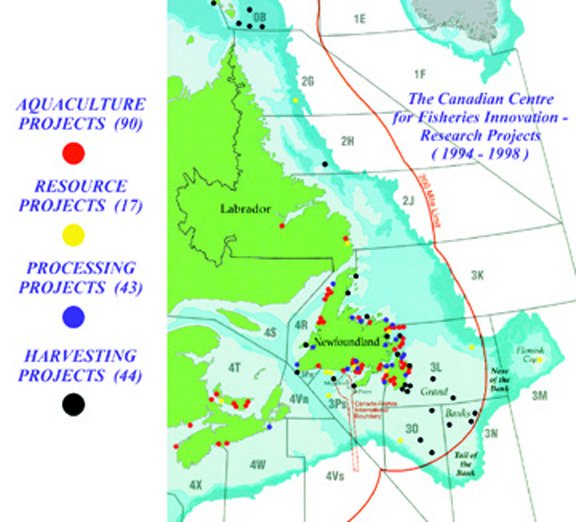

Recent fishery statistics indicate that the industry has rebounded from

the groundfish crisis of the early 1990s. While this renewal has resulted largely from the

unprecedented increase in shellfish stocks and the ability of the industry to take

advantage of it, the rebuilding has also benefited from research and development. The

impact that applied research and development has had on the renewal was recently examined

in an independent review of the Memorial University of Newfoundland (MUN)--based research

and development agency, the Canadian Centre for Fisheries Innovation (CCFI). The study

confirmed that research and development at CCFI has contributed in a major way to the

technical, scientific and economic advancements in aquaculture, harvesting, processing and

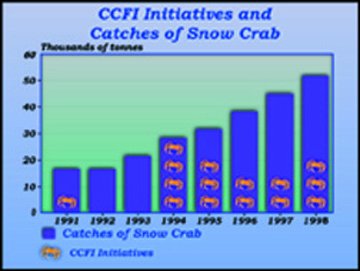

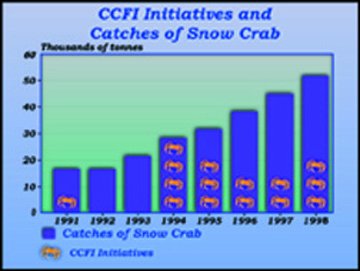

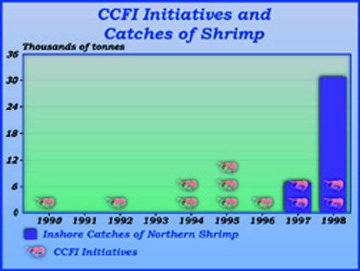

resource management. The number and timing of crab and shrimp initiatives by CCFI, along

with landings of these species, are indicated in the accompanying diagrams.

Crab

With respect to snow crab, where landings have doubled in four years, the

effect of research and development has been direct and lucrative. In 1994, CCFI began

working with industry on a strategic program for crab. Over the next four years, 11

projects regarding the processing of this species were undertaken. These projects included

an initiative with crab processors of the Fisheries Association of Newfoundland and

Labrador, which devised a leg cutting system that increased crab yields by 1 to 2%. At

recent catch and price levels, this initiative translated into at least 113 additional

tonnes of leg meat worth $1.5 million annually. In a related initiative, researchers

developed a dry extraction system for crab meat which enhanced the flavour, yield and

appearance of the product. The industry is now examining a variety of potential new

products made possible by this new technology. This improvement is expected to contribute

at least as much as the leg cutting technology to the industry.

With respect to snow crab, where landings have doubled in four years, the

effect of research and development has been direct and lucrative. In 1994, CCFI began

working with industry on a strategic program for crab. Over the next four years, 11

projects regarding the processing of this species were undertaken. These projects included

an initiative with crab processors of the Fisheries Association of Newfoundland and

Labrador, which devised a leg cutting system that increased crab yields by 1 to 2%. At

recent catch and price levels, this initiative translated into at least 113 additional

tonnes of leg meat worth $1.5 million annually. In a related initiative, researchers

developed a dry extraction system for crab meat which enhanced the flavour, yield and

appearance of the product. The industry is now examining a variety of potential new

products made possible by this new technology. This improvement is expected to contribute

at least as much as the leg cutting technology to the industry.

CCFI and research engineers at MUN also assisted St. John's-based Canpolar

East Inc. in developing a crab section cleaner. The new machinery reduces processing costs

by approximately 44 a pound, generating annual savings to the industry of $1 million to

$1.5 million. Sales of the machinery in the foreseeable future, just in Eastern Canada,

are expected to generate revenues for the St. John's company of close to $6 million.

Other crab initiatives include the development of crab au gratin products

from Rock and Toad Crab; the development of an au gratin product with crab and mussels;

and a current initiative to produce a superior quality crushed crab shell product for the

Asian markets.

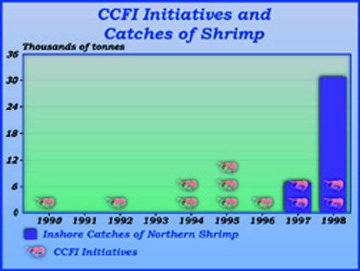

Shrimp

The second most important species to evolve in the Newfoundland fishery is

northern shrimp. The landed value is expected to reach $100 million in 1998. Research and

development on this species began in earnest in 1994. In that year, CCFI assisted two

firms in determining the feasibility of shrimp processing in their plants. As a result,

the companies were able to move quickly when the inshore shrimp fishery materialized.

The second most important species to evolve in the Newfoundland fishery is

northern shrimp. The landed value is expected to reach $100 million in 1998. Research and

development on this species began in earnest in 1994. In that year, CCFI assisted two

firms in determining the feasibility of shrimp processing in their plants. As a result,

the companies were able to move quickly when the inshore shrimp fishery materialized.

A major initiative, aimed at the industry as a whole, was launched in

1997. In that year, CCFI commissioned technical, financial and marketing studies on

requirements for establishing a Northern Shrimp fishery. Armed with the results, the

organization hosted ANorthern Shrimp: From Trawl

to Table@ an industry technology transfer event

just two weeks after the 1997 announcement of the inshore fishery allocations. The one-day

event presented information on the latest technologies and methods in harvesting, handling

and processing the species. According to one industry participant, the event advanced the

fishery by as much as two years.

General Initiatives

Individual plant initiatives have had an economic impact as well. MUN

researchers assisted Seafreez Foods Inc. in establishing a shrimp cocktail processing line

on the west coast of the Island in 1996. The initiative resulted in the production of 1.5

million bottles of product in the first year and the establishment of 16 new jobs.

Research developments are pushing forward economic growth in other areas

as well. The development of an anti-roll tank for 65-foot vessels has generated a great

deal of interest in the industry. It is estimated that increases in annual revenues per

vessel that have adopted this technology amount to approximately $35,000. Technological

advances in automatic detection of fish defects, developed by St. John's-based Canpolar

East Inc. in collaboration with MUN researchers, will dramatically reduce existing

detection costs and improve quality control. This technology has already attracted the

attention of international fish processing equipment companies. The processing of surimi,

the development of seal oil, and the ranching of sea urchins have also paid off for the

industry clients involved.

Future research and development in the fishery will continue to address

areas with greatest potential for commercial growth. Aquaculture of selected cold-water

species holds considerable promise, and researchers are already moving toward the

commercialization of certain of these species. Harvesting challenges for the foreseeable

future will involve enhanced selection of target species and sizes in different fisheries,

and in processing the emphasis will remain on the production of ever-greater high-quality

products and diversification.

Submitted by:

The Canadian Centre for Fisheries Innovation

CCFI is a joint venture of Memorial University of Newfoundland

and the Atlantic Canada Opportunities Agency.

Contents Previous Next

With respect to snow crab, where landings have doubled in four years, the

effect of research and development has been direct and lucrative. In 1994, CCFI began

working with industry on a strategic program for crab. Over the next four years, 11

projects regarding the processing of this species were undertaken. These projects included

an initiative with crab processors of the Fisheries Association of Newfoundland and

Labrador, which devised a leg cutting system that increased crab yields by 1 to 2%. At

recent catch and price levels, this initiative translated into at least 113 additional

tonnes of leg meat worth $1.5 million annually. In a related initiative, researchers

developed a dry extraction system for crab meat which enhanced the flavour, yield and

appearance of the product. The industry is now examining a variety of potential new

products made possible by this new technology. This improvement is expected to contribute

at least as much as the leg cutting technology to the industry.

With respect to snow crab, where landings have doubled in four years, the

effect of research and development has been direct and lucrative. In 1994, CCFI began

working with industry on a strategic program for crab. Over the next four years, 11

projects regarding the processing of this species were undertaken. These projects included

an initiative with crab processors of the Fisheries Association of Newfoundland and

Labrador, which devised a leg cutting system that increased crab yields by 1 to 2%. At

recent catch and price levels, this initiative translated into at least 113 additional

tonnes of leg meat worth $1.5 million annually. In a related initiative, researchers

developed a dry extraction system for crab meat which enhanced the flavour, yield and

appearance of the product. The industry is now examining a variety of potential new

products made possible by this new technology. This improvement is expected to contribute

at least as much as the leg cutting technology to the industry. The second most important species to evolve in the Newfoundland fishery is

northern shrimp. The landed value is expected to reach $100 million in 1998. Research and

development on this species began in earnest in 1994. In that year, CCFI assisted two

firms in determining the feasibility of shrimp processing in their plants. As a result,

the companies were able to move quickly when the inshore shrimp fishery materialized.

The second most important species to evolve in the Newfoundland fishery is

northern shrimp. The landed value is expected to reach $100 million in 1998. Research and

development on this species began in earnest in 1994. In that year, CCFI assisted two

firms in determining the feasibility of shrimp processing in their plants. As a result,

the companies were able to move quickly when the inshore shrimp fishery materialized.