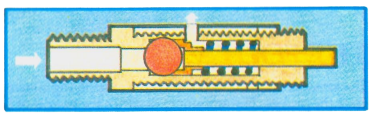

Reservoirs or tanks hold a supply of compressed air. A safety valve protects them from being over pressurized and bursting. The safety valve protects the air brake system from an excessive buildup of air pressure. The valve consists of a spring loaded ball that allows air to exhaust the reservoir pressure into the atmosphere. The valve’s pressure setting is determined by the force of the spring. A safety valve is normally set at 150 P.S.I. If the pressure in the system rises to approximately 150 P.S.I., the pressure would force the ball off its seat, allowing the pressure to exhaust through the exhaust port in the spring cage. When reservoir pressure is sufficiently reduced (to approximately 135 P.S.I.), the spring will force the ball back onto its seat, sealing off the reservoir pressure. Not all safety valves have a manual release feature as shown in the diagram below.

If the safety valve has to relieve the pressure, it indicates that the governor or compressor requires service or repair. This should be done by a qualified mechanic.

IMPORTANT! SAFETY VALVE ADJUSTMENTS MUST NOT BE TAMPERED WITH. ONLY QUALIFIED MECHANICS SHOULD SERVICE SAFETY VALVES.

Reservoirs or tanks are also equipped with drain cocks to drain off any moisture. When air is compressed, it becomes heated. The heated air cools in the reservoir, forming condensation. Oil leaking past the piston rings of the compressor mixes with this moisture to form a sludge in the bottom of the reservoir. If allowed to accumulate, this sludge (water and oil) would enter the braking system. An excess of water in the system causes trouble with valves and other parts. In winter, water in the system may freeze, causing malfunction of valves or brake chambers.

To minimize the amount of water collection, all tanks must be drained daily. Under extreme conditions, tanks may have to be drained more than once a day. Park the vehicle on a level surface, set the parking brake, block the vehicle’s wheels, open drain cocks fully. Allow all air pressure to escape, which will then permit the moisture collected in the tank to drain. Some tanks have more than one compartment and each compartment has its own drain cock. Briefly opening the valve just to allow some of the air to escape DOES NOT drain the moisture.

Some reservoirs are equipped with automatic reservoir drain valves (spitter valves). These may be drained manually by pushing up on a rod on the underside of the valve.

Most vehicles are equipped with more than one reservoir. This gives the system a larger volume of main reservoir air. As the first tank collects more of the moisture and oil from the compressor, it is called the ‘wet tank’. The second tank is usually further from the compressor and so collects drier or cleaner air. This tank is called the ‘dry tank’.

Reservoirs vary in size. The size of the tanks to be installed on a vehicle depends on the number and size of the brake chambers. Brake chambers with a 30 square inch diaphragm will obviously require a larger volume of reservoir air than those equipped with 20 square inch diaphragms.